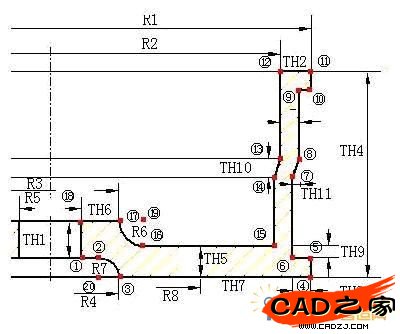

本文介绍了轮毂的ANSYS APDL命令流建模及模态分析实例相关内容。

ANSYS命令流及注释

五个辐条的轮毂

!

!初始化ANSYS环境

!

FINISH

/CLEAR !清空内存

/FILNAM,WHEEL5 !文件名

/TITILE,WHEEL5 PARAMETER MODELING !工作名

!

!定义几何尺寸参数

!

R1=180

R2=157

R3=75

R4=75

R5=30

R6=28

R7=20

R8=90

R9=60

S_HOLE=5

TH1=48

TH2=23

TH3=11

TH4=180

TH5=40

TH6=45

TH7=105

TH8=25

TH9=15

TH10=25

TH11=13

/VIEW,1,1,1,1 !改变视图

/ANG,1

/PNUM,LINE,1

/PNUM,AREA,1

/PNUM,VOLU,1

/NUMBER,1

!

!关键点

!

/PREP7

k,1,r5,r7,0

k,2,r4-ky(1),ky(1),0

k,3,r4,0,0

k,4,r1,0,0

k,5,kx(4),th5-th9,0

k,6,r1-th8,ky(5),0

k,7,kx(6),th4/2,0

k,8,kx(7)+th11,ky(7)+th10,0

k,9,kx(8),th4-th3,0

k,10,kx(4),ky(9),0

k,11,kx(4),th4,0

k,12,r2,ky(11),0

k,13,kx(12),ky(8),0

k,14,kx(7)-th3,ky(7),0

k,15,kx(14),th5,0

k,16,r3+r6,ky(15),0

k,17,kx(3),r7+th1,0

k,18,kx(1),ky(17),0

k,19,kx(16),ky(17),0

k,20,kx(2),0,0

k,21,0,0,0

k,22,0,th1+r7,0

*ask,s_hole,'the number of hole',5 !宏

!

!创建轮毂面

!

lstr,1,2 !连接1,2关键点,形成直线

larc,2,3,20,r7 !以20点为圆心r7为半径,2,3点为端点作弧线

lstr,3,4

lstr,4,5

lstr,5,6

lstr,6,7

lstr,7,8

lstr,8,9

lstr,9,10

lstr,10,11

lstr,11,12

lstr,12,13

lstr,13,14

lstr,14,15

lstr,15,16

larc,16,17,19,r6

lstr,17,18

lstr,18,1

al,all

cm,an-all,area !形成组件

!

!创建实体模型

!

allsel,all

vrotat,an-all,,,,,,21,22,360,S_hole, !旋转拉伸形成体

cm,v-an-all,volu

!

!减去孔洞

!

vsel,none

wpro,,-90, !绕Y轴转动工作平面

cswpla,11,1,1,1

csys,11

wpoff,r8*sin(180/s_hole),r8*cos(180/s_hole)

RPR4,3,-th5,th5/2,r9,, !创建三角形

adele,96

LFILLT,182,181,10, , !在直线182,181间形成半径10的圆角

LFILLT,182,183,10, ,

LFILLT,183,181,10, ,

LARC,98,100,21,144,

ldele,182

asel,none

al,181,184,187,185,183,186 !连接各线形成面

cm,sanjiao_hole,area

vext,sanjiao_hole,,,0,0,th5,,,, !以th5为厚度形成体

cm,v_hole,volu

vgen,s_hole,all,,,,360/s_hole,,,0 !旋转拉伸形成s_hole个体

cm,v-hole,volu

vsel,all

vsbv,v-an-all,v-hole !布尔运算减去体,形成孔洞

cm,v-an-all,volu

ALLSEL,ALL

!

!定义单元属性

!

et,1,solid45

mp,ex,1,71000 !铝合金材料特性

mp,nuxy,1,0.33

mp,dens,1,2720

!

!划分单元创建网格模型

!

SMRT,5 !自由网格划分

MSHAPE,1,3D

MSHKEY,0

FLST,5,5,6,ORDE,2

FITEM,5,11

FITEM,5,-15

CM,_Y,VOLU

VSEL, , , ,P51X

CM,_Y1,VOLU

CHKMSH,'VOLU'

CMSEL,S,_Y

VMESH,_Y1

finish

!

!保存

!

save

APLOT

/SOLU

FLST,2,5,5,ORDE,5 !约束固定

FITEM,2,19

FITEM,2,38

FITEM,2,57

FITEM,2,76

FITEM,2,95

/GO

DA,P51X,ALL,

*DEL,_FNCNAME !函数加载

*DEL,_FNCMTID

*DEL,_FNC_C1

*DEL,_FNCCSYS

*SET,_FNCNAME,'jiazai'

*DIM,_FNC_C1,,1

*SET,_FNC_C1(1),5

*SET,_FNCCSYS,11

! /INPUT,111.func,,,1

*DIM,%_FNCNAME%,TABLE,6,7,1,,,,%_FNCCSYS%

!

! Begin of equation: 1000*{X}/cos(180/s_hole)

*SET,%_FNCNAME%(0,0,1), 0.0, -999

*SET,%_FNCNAME%(2,0,1), 0.0

*SET,%_FNCNAME%(3,0,1), %_FNC_C1(1)%

*SET,%_FNCNAME%(4,0,1), 0.0

*SET,%_FNCNAME%(5,0,1), 0.0

*SET,%_FNCNAME%(6,0,1), 0.0

*SET,%_FNCNAME%(0,1,1), 1.0, -1, 0, 1000, 0, 0, 2

*SET,%_FNCNAME%(0,2,1), 0.0, -2, 0, 1, -1, 3, 2

*SET,%_FNCNAME%(0,3,1), 0, -1, 0, 180, 0, 0, 17

*SET,%_FNCNAME%(0,4,1), 0.0, -3, 0, 1, -1, 4, 17

*SET,%_FNCNAME%(0,5,1), 0.0, -1, 10, 1, -3, 0, 0

*SET,%_FNCNAME%(0,6,1), 0.0, -3, 0, 1, -2, 4, -1

*SET,%_FNCNAME%(0,7,1), 0.0, 99, 0, 1, -3, 0, 0

! End of equation: 1000*{X}/cos(180/s_hole)

FLST,2,3,1,ORDE,3 !确定加载点位置

FITEM,2,37

FITEM,2,54

FITEM,2,354

/GO

F,P51X,FX, %JIAZAI%

/STATUS,SOLU !求解

SOLVE

/VIEW,1,1,1,1

/ANG,1

/REP,FAST

/SOLU

ANTYPE,2 !模态求解

MSAVE,0

MODOPT,LANB,10

EQSLV,SPAR

MXPAND,10, , ,1

LUMPM,0

PSTRES,0

MODOPT,LANB,10,0,0, ,OFF

/STATUS,SOLU

SOLVE

FINISH

Save

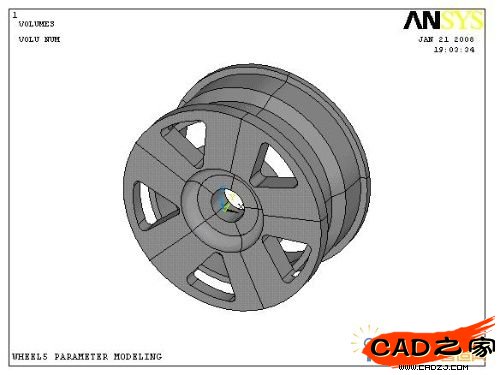

模型图

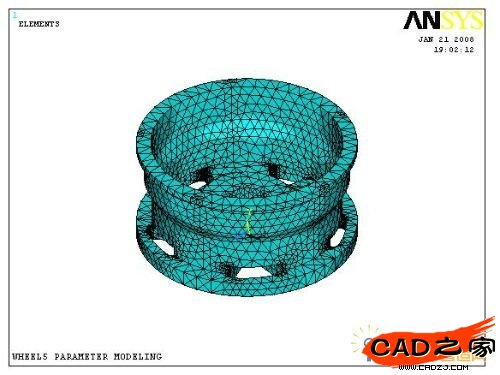

网格划分

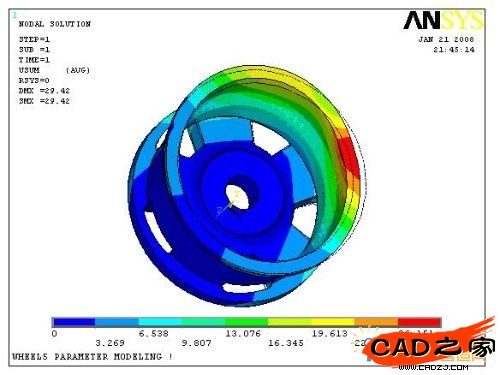

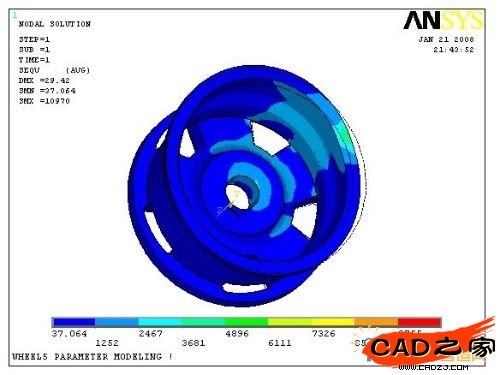

位移图

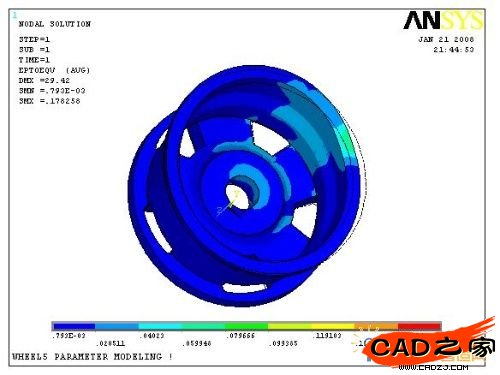

应变图

应力图

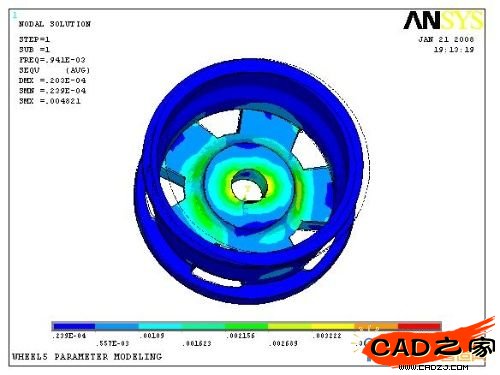

应力模态(其中之一)

相关文章

- 2021-09-08BIM技术丛书Revit软件应用系列Autodesk Revit族详解 [

- 2021-08-30电气CAD实例教程AutoCAD 2010中文版 [左昉 等编著] 20

- 2021-08-24经典实例学设计AutoCAD 2016从入门到精通 [李轲 编著]

- 2021-08-21AutoCAD 2013建筑设计与实例精讲中文版 [本社 编] 201

- 2021-08-21AutoCAD 2013建筑设计与施工图绘制实例教程中文版 [麓

- 2021-08-21AutoCAD 2013机械绘图实例教程中文版 [陈志民 等编著]

- 2021-08-20AutoCAD 2012机械绘图基础与实例中文版 [田蕴 编] 201

- 2021-08-18完全实例自学AutoCAD 2012机械绘图 [唯美科技工作室

- 2021-08-18完全实例自学AutoCAD 2012建筑绘图 [唯美科技工作室

- 2021-08-12AutoCAD 2012机械绘图基础与实例中文版 [田蕴 编] 201